.jpg)

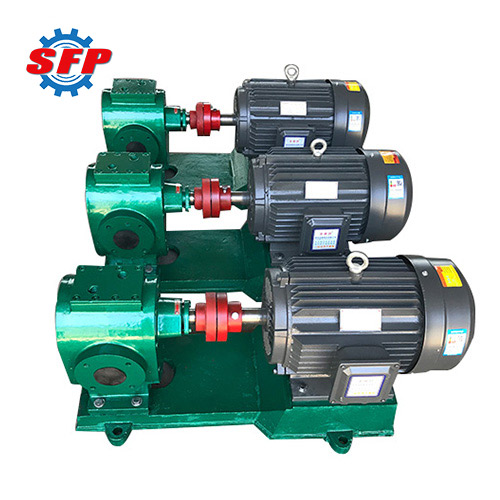

LCB bitumen gear pump is suitable for conveying non-corrosive, non-solid particles and solidifiable medium at room temperature in textile, power station, food, agriculture, construction, paper making and industries. The outlet and inlet of this equipment are equipped with hollow jacket and flange, which can be heated and cooled by heat-conducting oil, steam and hot water for conveying liquid and pump, so it can meet the conveying requirements of outdoor installation in high-cold areas and occasions where process medium needs heat preservation.

.png)

LCB series insulation gear pumps can deliver non-corrosive, non-solid particles, solidifiable media at room temperature. It is particularly applied to outdoor installation of cold areas and process media need thermal insulation occasions, the medium temperature up to 300 ℃, viscosity of 5~1500 cst. The pump is designed for room temperature curing, outdoor installation of cold areas and process media need thermal insulation occasions designed for thermal oil, steam, hot water, cold water and other media with the use of the need to transport the liquid and the pump transported media for heating, transporting and cooling.

| Model | Rated Flow rate | Working Pressure MPA | Vacuum Suction Height | Diameter (mm) |

Motor Power | |

| L/min | m³/h | |||||

| LCB1/0.36 LCB1/0.6 |

16.6 | 1 | 0.36 0.6 |

3 | 25 | 1.5 1.5 |

| LCB2/0.36 LCB2/0.6 |

33.3 | 2 | 0.36 0.6 |

3 | 25 | 1.5 2.2 |

| LCB3/0.36 LCB3/0.6 |

50 | 3 | 0.36 0.6 |

3 | 25 | 1.5 2.2 |

| LCB4/0.6 LCB4/1.0 |

66.4 | 4 | 0.6 1.0 |

5 | 30 | 1.5 2.2 |

| LCB5/0.36 LCB5/0.6 |

83.3 | 5 | 0.36 0.6 |

5 | 40 | 2.2 4.0 |

| LCB6/0.36 LCB6/0.6 |

100 | 6 | 0.36 0.6 |

5 | 40 | 3.0 4.0 |

| LCB7/0.6 LCB7/1.0 |

116 | 7 | 0.6 1.0 |

5 | 50 | 3.0 4.0 |

| LCB10/0.6 LCB10/1.0 |

167 | 10 | 0.6 1.0 |

5 | 50 | 4.0 5.5 |

| LCB12/0.36 LCB12/0.6 |

200 | 12 | 0.36 0.6 |

5 | 55 | 4.0 5.5 |

| LCB18/0.36 LCB18/0.6 |

300 | 18 | 0.36 0.6 |

5 | 70 | 5.5 7.5 |

| LCB25/0. 6 | 416 | 25 | 0.6 | 5 | 100 | 7.5 |

| LCB29/0.36 LCB29/0.6 |

483.3 | 29 | 0.36 0.6 |

5 | 70 | 7.5 11.0 |

| LCB38/0.36 LCB38/0.6 |

633 | 38 | 0.36 0.6 |

5 | 100 | 11.0 15.0 |

| LCB58/0.36 LCB58/0.6 |

960 | 58 | 0.36 0.6 |

5 | 18.5 22 |

|

.png)