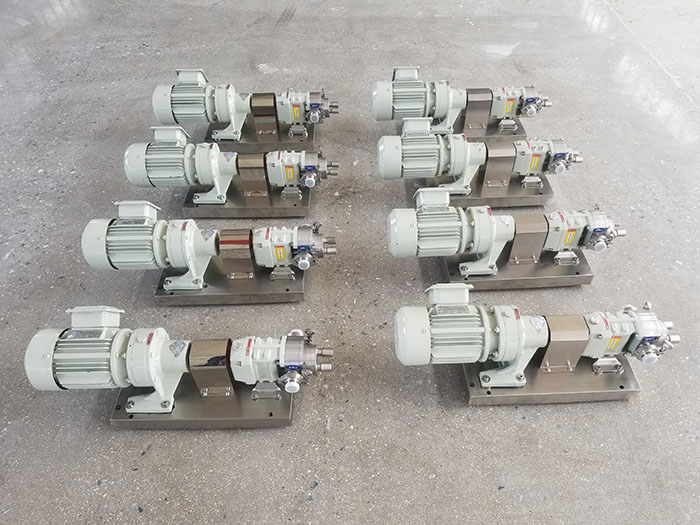

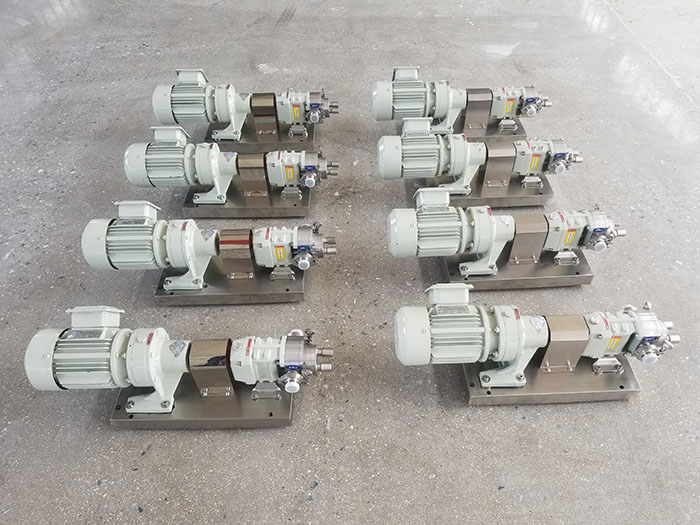

Food grade stainless steel rotor pump. Rotor pump is also called colloid pump, rotary pump, three-vane pump, universal pump and so on. Rotor pump belongs to volumetric pump. It achieves the purpose of conveying fluid by means of the periodic conversion of several fixed volume conveying units in the working cavity. The mechanical energy of the prime mover is directly converted into the pressure energy of conveying fluid through the pump, and the flow rate of the stainless steel rotor pump only depends on the volume change of the working cavity and its changing frequency in the unit time, and has nothing to do with the discharge pressure; the rotor pump actually works through a pair of synchronous rotors. The rotor is driven by a pair of synchronous gears in the box, and the rotor rotates synchronously in the opposite direction driven by the main shaft and auxiliary shaft. The volume of the stainless steel rotor pump is changed, thus forming a higher vacuum and discharge pressure. It is especially suitable for the transportation of sanitary medium and corrosive and high viscosity medium. Recently, I received a customer who said that their machines were all good and used all the time. Stainless steel rotor pump cavities are often cleaned after use, but recently there is a very loud noise in the gearbox, which was only a little bit ignored at first, and then it got bigger and bigger. I'd like to ask what the reason is. When we received the customer's problem, we immediately thought of the possibility that there was too little oil in the gearbox and quickly gave a solution. The customer side also asked the technician to add and drop the gearbox, and then power on the test to get a perfect solution directly.

1. Seals and pump seals are divided into static seals and moving seals. The sealing ring of static seals should pay attention to no scratches or bruises on the surface, otherwise, it will directly affect the sealing effect; for moving seals, because it will be corroded by pressure and conveying medium, as well as the wear of particles in the medium and many other factors, if slightly careless, leakage is likely to occur. Once the product leaks, it should be stopped and repaired in time, wiped with a soft and clean cotton cloth and coated with a layer of glycerin. after assembly, the machine can be turned on before it can be used by hand. if there is no hope of repair, new parts should be replaced.

2. Lubricating parts, the transmission gears and rolling bearings of the pump must maintain good lubrication conditions. at ordinary times, always pay attention to the level of oil in the gears and give enough lubricating oil. and to ensure that the oil quality is pure, clean, and change the new oil regularly (six months or a year).

3. The electrical system, around the electrical equipment, is not allowed to store instruments, substances or gases that destroy insulation. At the same time, the electrical equipment must be kept working in a dry environment. Moistureproof facilities should be added if it is difficult to avoid.

4. daily maintenance, whenever the machine is not working, the corresponding cleaning agent will be selected according to the nature of the conveying material, and the pump will be cleaned effectively. Finally, the pump will be cleaned with clean water to ensure the cleanliness and hygiene of the pump.