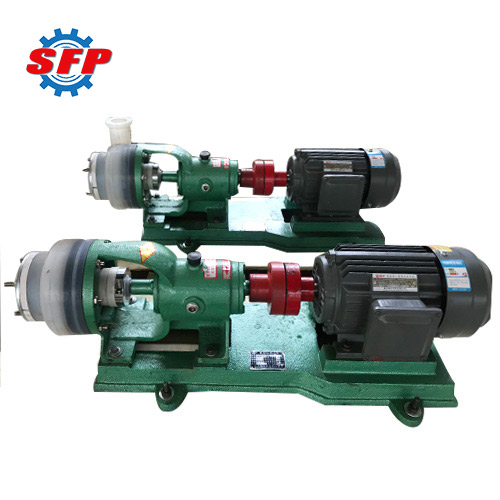

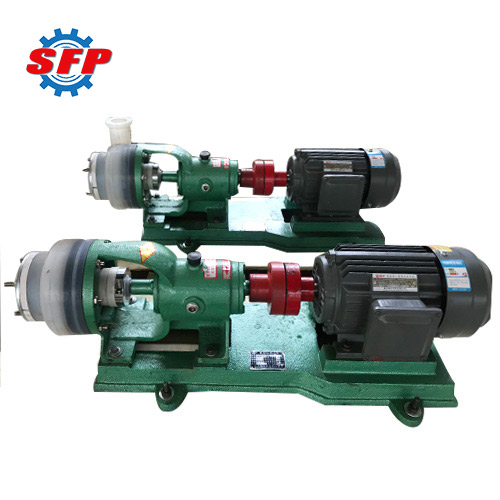

The fluoroplastic alloy centrifugal pump combines the advantages of various fluorine plastics, has strong corrosion resistance, and has the advantages of high mechanical strength, no aging, and no toxin decomposition. The product has high mechanical strength, reasonable design, compact structure, reliable performance, convenient use and maintenance, smooth and efficient flow path and energy saving. However, there is a issues about seals that may come up during the operation of fluoroplastic centrifugal pump. The following shows the 4 fluoroplastic chemical pump Seal repair points.

1. The good sealing performance of fluoroplastic chemical pumps is improved with the elasticity of the spring. This idea is incorrect, if the spring of the chemical pump is compressed too much, it will lead to a significant increase in friction, which will lead to increased wear and tear of the fluoroplastic chemical pump, and in severe cases, the parts will be burned. In addition, if the spring performance of the chemical pump is too good, the seal of the chemical pump may also fail.

2. A tighter sealing ring is preferable for the fluorine plastic centrifugal pump. Chemical pump seals made of fluoroplastic are more damaging to equipment when they are overly tight, as this causes wear and strain on the bearings at a greater degree. When it becomes inconvenient to adjust the bearing, there is an increase in the resistance to the bearing's rotation. Ultimately, an overly tight seal will cause the object to deform. In short, the sealing action is rather counterproductive.

3. The new chemical pump made of plastic is superior to the previous one. In theory, the new fluoroplastic chemical pump performs better than the old chemical pump. However, in actual use, there may be a significant size difference that affects the fluoroplastic pumps' sealing performance because of the new fluoroplastic chemical transfer pump's quality, which we are not initially aware of. Consequently, it is preferable to avoid replacing the new fluoroplastic chemical pump when it comes to permeable media conveyance if there isn't any significant wear and tear. Because the chemical pump's static ring remains in a static position for an extended period of time, sediment will gather together, which is beneficial.

4. The tighter the better for the corrosion resistanc fluorine plastic chemical pump impeller blade lock mother. Shaft leakage and chemical pump bearings happen in the midst of the two phenomena more often in mechanical seal leakage. We all believe that the reason for the leaking occurrence in fluoroplastic chemical pumps is a loosely positioned lock latch on the impeller blade. Leakage, however, can result from a wide range of additional reasons. If the underlying source of the leak is not found, tightening the locking nut on the chemical pump's impeller will merely make the inter-axial gasket less effective.