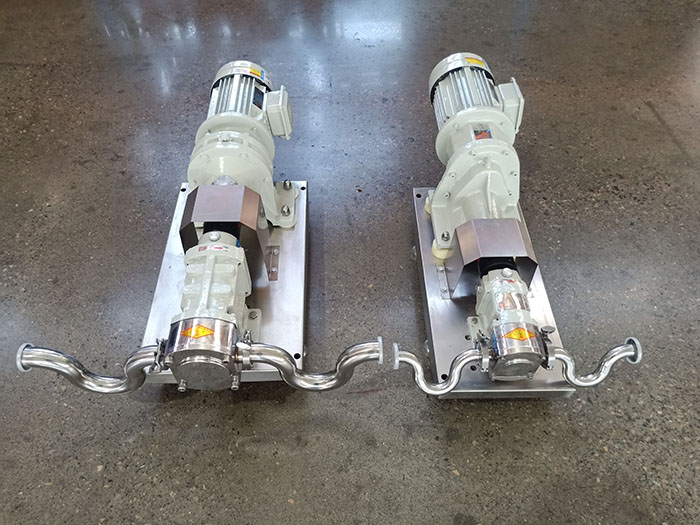

Stainless steel cam pumps are widely used in various industries for their durability and high performance. One critical aspect of maintaining optimal performance is ensuring the proper adjustment of the rotor gap. In this article, we will discuss an effective method for adjusting the rotor gap in stainless steel cam pumps.

Understanding the Rotor Gap:

The rotor gap refers to the distance between the rotor and the pump casing. An appropriate rotor gap is necessary to ensure efficient fluid flow and prevent any damage to the pump components. A gap that is too small can cause excessive friction and wear, while a gap that is too large can result in reduced efficiency and performance.

Preparations:

Before adjusting the rotor gap, it is essential to follow certain preparations. Firstly, ensure the pump is turned off and disconnected from the power source. Secondly, wear appropriate safety gear, such as gloves and goggles, to protect yourself from any potential hazards.

Tools Required:

To adjust the rotor gap, you will need a set of feeler gauges, commonly available in various thicknesses. These gauges help measure the gap accurately.

Adjustment Process:

Follow these steps to adjust the rotor gap effectively:

a. Locate the adjustment screws: Stainless steel cam pumps typically have two adjustment screws, positioned opposite each other. These screws control the rotor gap.

b. Loosen the lock nuts: Use an appropriate wrench to loosen the lock nuts on the adjustment screws. This will allow you to make adjustments to the rotor gap.

c. Measure the existing gap: Insert a feeler gauge between the rotor and the pump casing. Gently move the gauge back and forth to determine the current gap size. Note down the measurement.

d. Adjust the gap: With the lock nuts loosened, use the feeler gauge to adjust the rotor gap. Gradually increase or decrease the gap size by turning the adjustment screws clockwise or counterclockwise.

e. Check the gap: After making adjustments, remove the feeler gauge and check the new gap size. Ensure it is within the manufacturer's recommended specifications.

f. Tighten the lock nuts: Once the desired rotor gap is achieved, use the wrench to tighten the lock nuts on the adjustment screws. This will secure the gap in place.

Testing and Maintenance:

After adjusting the rotor gap, it is crucial to test the pump's performance. Turn on the pump and observe its operation. Check for any unusual noises or vibrations that could indicate an improper gap adjustment. Regular maintenance, including periodic rotor gap checks, will help ensure the pump's long-term efficiency.

Proper adjustment of the rotor gap is vital for maintaining the optimal performance of stainless steel cam pumps. By following the method outlined in this article, operators can effectively adjust the rotor gap, ensuring efficient fluid flow and prolonging the pump's lifespan. Regular monitoring and maintenance are key to achieving reliable and consistent performance from stainless steel cam pumps.