Through the transformation of the mechanical seal structure of the

KCB stainless steel gear pump and the reasonable selection of washing solution, the performance of the mechanical seal is improved, the problem of frequent leakage of the mechanical seal is solved, the maintenance and maintenance costs of the equipment are reduced, and the continuous and stable production of the device is ensured. Because the KCB stainless steel gear pump is located at the bottom of the gas lift tower, the rust, impurities and recombination polymers of pipes and equipment are deposited at the bottom of the tower, and the residual oil entering the KCB stainless steel gear pump contains a lot of impurities and polymers. At the same time, due to insufficient washing, these impurities and polymers inevitably deposit in the sealing cavity, resulting in blocking the gap between the moving ring and the moving ring seat and the shaft sleeve. As a result, the action of the moving ring in the axial direction is inflexible or even stuck, the spring is stuck and can not provide the end face specific pressure of the originally designed 0.586MPa, resulting in the sealing surface can not be well bonded, the liquid film balance is destroyed, and the seal will appear micro-leakage. as the polymer and impurity particles enter the end face of the friction pair, the sealing surface is gradually worn, coupled with the ineffective axial compensation of the moving ring, resulting in an increase in seal leakage. Eventually lead to complete failure of the seal.

According to the failure reasons of the seal, we have carried out the technical transformation from the following aspects: according to the specific working conditions of the KCB stainless steel gear pump, we choose the mechanical seal (assembly type) and its main characteristics are as follows: accurate centering is realized through the automatic locking ring. The adjustable gland can be used directly with common bolts, and the installation of the container structure is convenient. The spring is located on the outside of the auxiliary sealing ring and is completely separated from the media to avoid the sticking of the spring. The moving ring adopts the whole floating non-mosaic, while the static ring is designed in z shape through computer analysis, which has the advantage of good heat dissipation and should not accumulate heat.

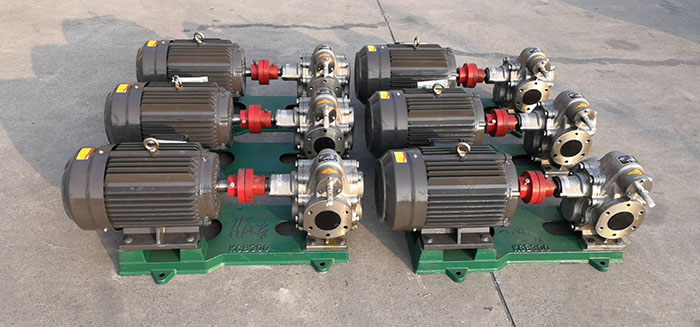

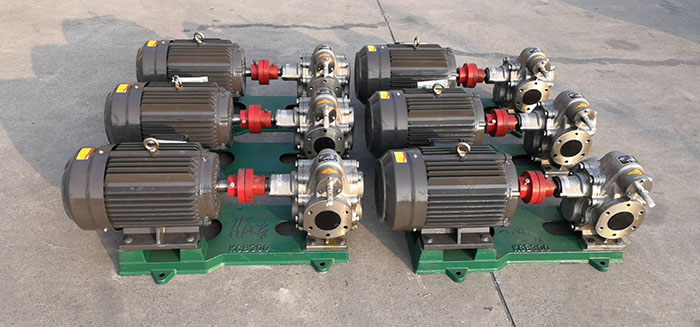

Stainless steel gear pumps are mainly used in water systems with low flow and high lift, such as drinking water supply system, pressure boiler water supply system, high purity water purification system, as well as washing and spraying processes in pharmaceutical, food, fine chemical, paper and other industries.