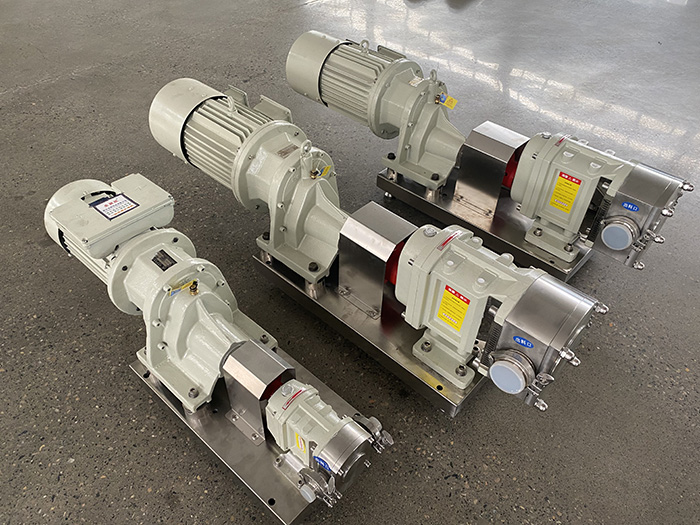

The use of a

food grade stainless steel rotary lobe pump is essential for transporting chocolate in the food processing industry. This type of pump ensures the safe and hygienic transfer of chocolate while maintaining its quality and consistency. In this article, we will explore the features and benefits of using a food-grade stainless steel rotary lobe pump for chocolate processing, highlighting its importance in maintaining product integrity and meeting food safety standards.

1. Material Compatibility:

A food-grade stainless steel rotary lobe pump is specifically designed to handle food products like chocolate. Stainless steel is a non-reactive material that is resistant to corrosion, ensuring that the pump does not contaminate the chocolate with unwanted flavors or impurities. It also provides excellent durability, withstanding the demands of continuous operation and high viscosity fluids.

2. Hygienic Design:

The pump's hygienic design is crucial in the food processing industry, especially when handling consumable products like chocolate. Food-grade pumps feature smooth surfaces, easy-to-clean components, and minimal dead spaces, reducing the risk of bacterial growth and ensuring thorough cleaning. The absence of crevices and sharp edges prevents product build-up, allowing for efficient sanitation and reducing the chances of cross-contamination.

3. Gentle Product Handling:

Chocolate is a delicate product that requires gentle handling to maintain its smooth texture and consistency. The rotary lobe pump's design allows for gentle transfer, minimizing shear and preventing damage to the chocolate particles. This ensures that the chocolate retains its taste, appearance, and overall quality throughout the pumping process.

4. Precise Flow Control:

Chocolate processing often requires precise flow control to maintain the desired consistency and to prevent product waste. Food-grade stainless steel rotary lobe pumps offer variable speed control, allowing operators to adjust the flow rate as needed. This feature enables precise dosing during filling, coating, and other chocolate processing operations, ensuring efficient production and minimizing product loss.

5. Compliance with Food Safety Standards:

In the food industry, maintaining food safety standards is of utmost importance. Food-grade stainless steel rotary lobe pumps are designed to meet strict sanitary requirements and regulations. These pumps are often certified to comply with industry standards such as FDA, EHEDG, and 3A, ensuring that the chocolate remains safe for consumption and meets the highest quality standards.

6. Versatility in Chocolate Processing:

Food-grade stainless steel rotary lobe pumps are highly versatile and can be used for various chocolate processing applications. Whether it's transferring melted chocolate from storage tanks to tempering machines, pumping chocolate fillings into molds, or circulating chocolate during the conching process, these pumps provide consistent and reliable performance.

The use of a food-grade stainless steel rotary lobe pump is crucial in chocolate processing to ensure product integrity, meet food safety standards, and maintain efficient production. The pump's material compatibility, hygienic design, gentle product handling, precise flow control, and compliance with food safety regulations make it an ideal choice for the food industry. By investing in a high-quality food-grade stainless steel rotary lobe pump, chocolate manufacturers can enhance their production processes, ensure product quality, and meet consumer expectations for safe and delicious chocolate products.