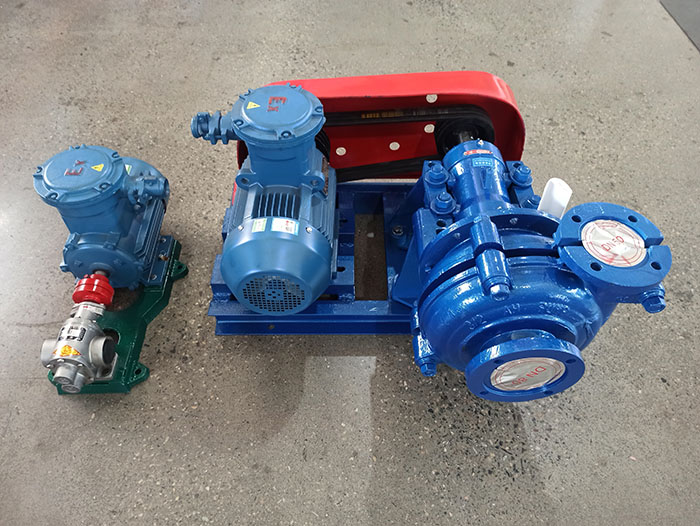

Single stage mine slurry pumps are vital equipment in mining operations, specifically designed to handle abrasive and corrosive slurries. In this article, we will delve into the conditions of use that optimize the performance and longevity of single stage mine slurry pumps in demanding mining environments.

Slurry Characteristics:

Understanding the characteristics of the slurry being handled is crucial for the proper operation of a single stage mine slurry pump. Factors such as particle size, density, viscosity, and abrasiveness of the slurry must be considered. This knowledge helps in selecting the appropriate pump materials, impeller design, and operating parameters to ensure efficient pumping and minimize wear.

Pump Material Selection:

The selection of pump materials is critical to withstand the harsh conditions of mining slurries. Wear-resistant materials such as high-chrome alloys, rubber, or polyurethane are commonly used for the pump casing, impeller, and other wetted parts. Choosing the right material combination based on the slurry's corrosive properties and abrasiveness is essential for extended pump life and reduced maintenance.

Proper Seal and Bearing Protection:

Mining slurries can be highly abrasive and corrosive, posing challenges to pump seals and bearings. It is important to select robust sealing systems, such as mechanical seals or gland packing, that can withstand the slurry's aggressive nature. Additionally, implementing effective bearing protection measures, such as external flush or labyrinth seals, prevents slurry infiltration and prolongs bearing life.

Operating Parameters:

Optimizing operating parameters ensures the efficient and reliable performance of a single stage mine slurry pump. Parameters such as flow rate, head, and speed should be carefully adjusted to match the specific requirements of the slurry being pumped. Operating within the recommended range helps maintain the pump's hydraulic efficiency, reduces energy consumption, and minimizes wear and tear.

Regular Maintenance and Inspection:

Regular maintenance and inspection are crucial for the longevity and trouble-free operation of single stage mine slurry pumps. This includes routine checks of pump components, monitoring of vibration and temperature, lubrication of bearings, and replacement of worn parts. Periodic inspections help identify potential issues early on, allowing for timely repairs or replacements to prevent costly pump failures.

Proper Installation and Alignment:

Correct installation and alignment of the pump are fundamental to its performance and reliability. Ensuring proper foundation, alignment of the pump with the motor, and alignment of the pump shaft with the driver shaft minimize vibration, improve efficiency, and prevent premature failures. Following manufacturer guidelines and seeking professional assistance during installation can significantly enhance the pump's operational life.

Single stage mine slurry pumps are essential for handling abrasive and corrosive slurries in mining operations. By considering the slurry characteristics, selecting appropriate materials, implementing effective sealing and bearing protection, optimizing operating parameters, performing regular maintenance, and ensuring proper installation, the performance and longevity of these pumps can be maximized. Adhering to these conditions of use enhances efficiency, reduces downtime, and lowers maintenance costs, thereby contributing to the overall productivity and profitability of mining operations.